Popsicle sticks are mainly used as packaging materials for ice cream and other cold drinks. In China, they are made of birch and other materials, and are made through processes such as lumbering, steaming, peeling, rotary cutting, punching, drying, polishing, sorting, inspection, and packaging. They have the characteristics of smooth texture and moderate strength. This article will discuss the main materials of popsicle sticks and the common material advantages.

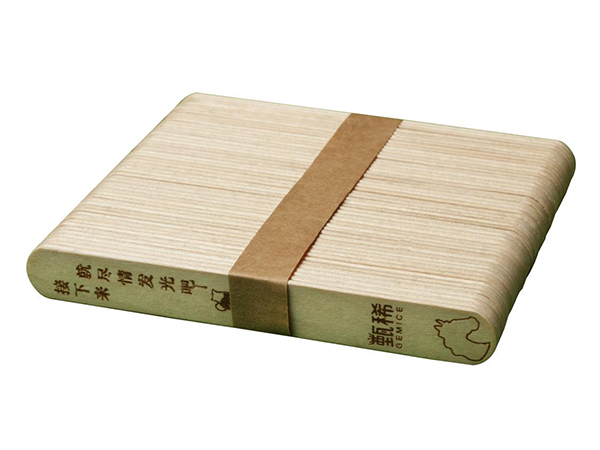

Usually, wooden popsicle sticks are common on the market (including birch, beech, pine, etc.), followed by bamboo, PLA, and plastic.

1. Wooden: Most markets use birch to produce popsicle sticks because birch is relatively hard, has moderate density, good wear resistance, and is easy to cut and carve. Wooden popsicle sticks are suitable for mass production, and have the highest cost-effectiveness. The second is beech, which is harder than birch and more difficult to process than birch and pine. It requires stronger tools and higher technology, but the finished product is more durable. Finally, pine is relatively soft and easy to process. It is suitable for rapid mass production, but due to its soft properties, it is more fragile, and the durability of the finished product is slightly worse.

2. Bamboo: Bamboo is renewable and grows fast, which meets the requirements of sustainable development.

3. PLA material: The raw materials come from renewable plant resources such as corn starch and sugarcane. They are made through fermentation, dehydration, polymerization, and other processes. The production process has low-carbon and environmentally friendly characteristics and meets the concept of sustainable development.

4. Plastic material: It is a non-degradable material, has a great impact on the environment, and is easy to break and deform.

Many businesses customize wooden/bamboo ice cream sticks for promotional purposes and to make limited edition products, for example:

1. Packaging Customization: offers a wide range of material options, including paper, plastic, and so on.

2. Logo Branding: allows you to clearly engrave intricate patterns or text on your products, ensuring your brand logo stands out. Whether it's for promotional items, corporate gifts, or retail products, logo embossing adds a touch of professionalism and exclusivity.

3. Laser Engraving: By printing QR codes on your items, you can facilitate product tracking and management and provide additional information to consumers. This technology also enables interactive experiences, such as linking to websites, instructional videos, or promotional content.

Wooden/Bamboo Sticks are free from harmful chemicals like BPA, and they comply with food safety standards, ensuring safe contact with food. We have a 100,000-grade clean production workshop. Production personnel strictly follow a dust-free operation process, and we have many product safety certificates, like BRC, FSC, FSSC22000, ISO9001, FDA, Halal, and Arbon Verification.

At Sanyang, we have decades of bamboo and wood-based experience. We monitor the entire process involved in creating our ice cream and popsicle sticks, from harvesting the tree to enjoying a frozen treat. We offer extensive testing, backed by industry certifications, to ensure ecological responsibility, efficient production, quality control, and consumer safety.